The Art of Eightfold Polishing: How Japanese Sword Masters Achieve the Perfect Mirror Finish

The Art of Eightfold Polishing: How Japanese Sword Masters Achieve the Perfect Mirror Finish

Introduction: The Quest for the Divine Edge

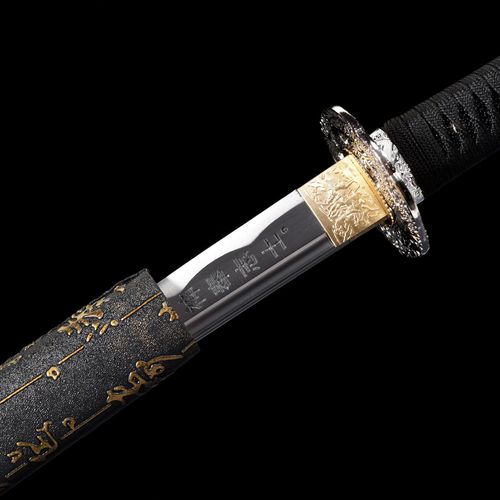

In the quiet glow of a traditional Japanese sword polishing workshop, a master togishi (研師) performs his sacred craft—not with power tools, but with eight carefully selected grinding stones, each finer than the last. This is Hakutōgi-no-Metsuke (白砥ぎの目付け), the legendary "eight-fold polishing" process that transforms rough steel into a blade so refined it can reflect a samurai's soul.

At LOONG BLADE, we preserve this centuries-old tradition, ensuring every katana achieves not just sharpness, but perfection in every facet.

Chapter 1: Why Eight Steps? The Spiritual Geometry of the Katana

Unlike Western polishing methods that prioritize speed, Japanese sword polishing follows a sacred progression:

| Polishing Stage | Stone Grit | Purpose | Spiritual Meaning |

|---|---|---|---|

| Binsui (備水砥) | #120-180 | Shaping | "Removing the mountain" – rough form |

| Kaisei (改正砥) | #320-400 | Beveling | "Finding the path" – defining geometry |

| Chū-nagura (中名倉) | #600-800 | Smoothing | "Softening the spirit" – harmonious lines |

| Shiage-to (仕上砥) | #1000-1200 | Refining | "Awakening the edge" – revealing hada grain |

| Uchigumori (内曇砥) | Natural Stone | Burnishing | "Clouds on water" – creating misty finish |

| Jizuke (地付け) | Hazuya | Final Polish | "Mirror of the soul" – perfecting the ji (surface) |

| Hadori (刃取り) | Nugui | Edge Brightening | "Sun on steel" – illuminating hamon |

| Migaki (磨き) | Finger Stones | Final Luster | "Dew on petals" – ultimate refinement |

Each stage removes the scratches of the previous stone—not by grinding, but by replacing coarse marks with finer ones, like a painter layering translucent washes of ink.

Chapter 2: The Living Stones – Nature’s Hidden Gems

Authentic Japanese polishing uses natural sedimentary stones, each with unique properties:

- Narutaki Stones (鳴滝砥石): Mined near Kyoto, these create the soft "pearl skin" texture (ji-gane)

- Aoto Stones (青砥): Blue-green schist that reveals the steel’s folded grain (hada)

- Uchigumori (内曇砥): Rare claystone producing the signature misty finish

At LOONG BLADE, we source stones from the same quarries used by Edo-period smiths.

Chapter 3: The Polisher’s Secret Techniques

1. The 45° Angle Rule

Every stroke follows the blade’s mune (spine) at precisely 45°—the angle that:

- Preserves the shinogi ridge line

- Avoids over-thinning the ha (edge)

2. Water as a Partner

The perfect slurry mix:

- Too wet = Loses abrasiveness

- Too dry = Scratches the steel

3. The "Singing Stone" Test

Master polishers listen to the stone’s pitch—a high ring means proper pressure.

Chapter 4: Modern Meets Traditional – LOONG BLADE’s Approach

While we honor tradition, we enhance precision with:

✅ Digital Microscopy: Ensures uniform scratch patterns

✅ Laser-Guided Stone Alignment: Perfect angle consistency

✅ Hybrid Stones: Natural base with synthetic grit for controlled wear

Conclusion: More Than a Finish – A Meditation

Eightfold polishing isn’t just about shine; it’s a 320-hour Zen koan in steel:

- Patience – Rushing any step ruins the final mirror

- Humility – The stone teaches as much as the master

-

Perfection – Not in absence of flaws, but in harmony of all elements