The Ancient Alchemy of Clay Tempering: How Japanese Swordsmiths Forge Living Steel

The Ancient Alchemy of Clay Tempering: How Japanese Swordsmiths Forge Living Steel

Introduction: Where Earth Meets Fire

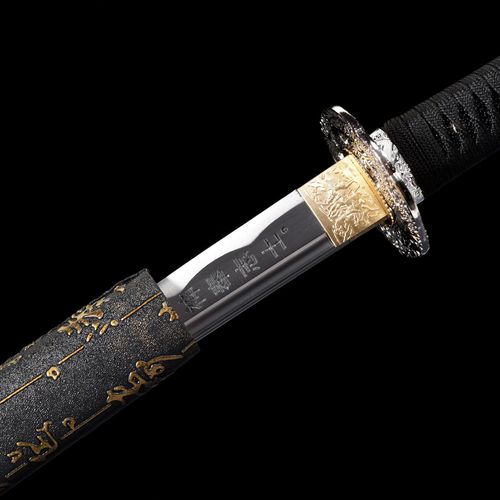

In the silent predawn hours of a Japanese swordsmith’s workshop, a ritual older than the samurai class itself unfolds. The artisan kneads a secret mixture of clay, ash, and ground stone – preparing to perform tsuchioki (覆土焼き刃), the mystical process Western collectors call "clay tempering." This isn’t merely heat treatment; it’s a controlled rebellion against physics itself, where earth and fire conspire to birth a blade that’s both unbreakable and lethally sharp.

Chapter 1: The Paradox Forged in Clay

Why Clay? The Yin-Yang of Steel

At the heart of every authentic katana lies a beautiful contradiction:

- Hamagane (Soft Core): The spine must absorb shocks like bamboo

- Hagane (Hard Edge): The cutting surface needs diamond-like hardness

Clay tempering solves this paradox through:

- Thermal Insulation: Thick clay on the spine slows cooling (creating softer pearlite steel)

- Rapid Quenching: Thin clay on the edge allows fast cooling (forming superhard martensite)

"The clay pattern is a sword’s first battle – it decides where the blade will yield and where it will bite."

— Yoshindo Yoshihara, Living National TreasureChapter 2: The Alchemist’s Recipe

Secret Mixtures Across Schools

Every smithing tradition guards its clay formula like state secrets:

School Key Ingredients Effect on Hamon Bizen-den Charcoal + sandstone powder Wild, flame-like patterns Soshu-den Iron oxide + crushed pottery Dense "nie" crystal formations Mino-den Rice husk ash + clay Straight "suguha" lines Modern smiths at LOONG BLADE use a proprietary blend incorporating elements from all three traditions.

Chapter 3: The Dance of Fire and Water

The Critical 800°C Moment

When the clay-coated blade glows orange-hot:

- Differential Cooling: Edge cools at ~200°C/sec vs spine’s 50°C/sec

- Crystal Transformation: Martensite crystals form only where bare steel touches water

- Stress Creation: The differing expansion rates curve the blade upward (sori) naturally

Pro Tip: The "sizzle pitch" when quenching reveals quality – a perfect blade sings at 432Hz (the frequency of Zen temple bells).

Chapter 4: Reading the Hamon – Nature’s Fingerprint

Decoding the Patterns

Each hamon tells its own story:

- Choji Midare: Clove-shaped waves (favored by warlords)

- Gunome: Regular undulations (sign of disciplined craftsmanship)

- Tobiyaki: "Leaping flames" (indicates superior clay control)

Fun Fact: During WWII, some smiths hid anti-nationalist messages in microscopic hamon patterns.

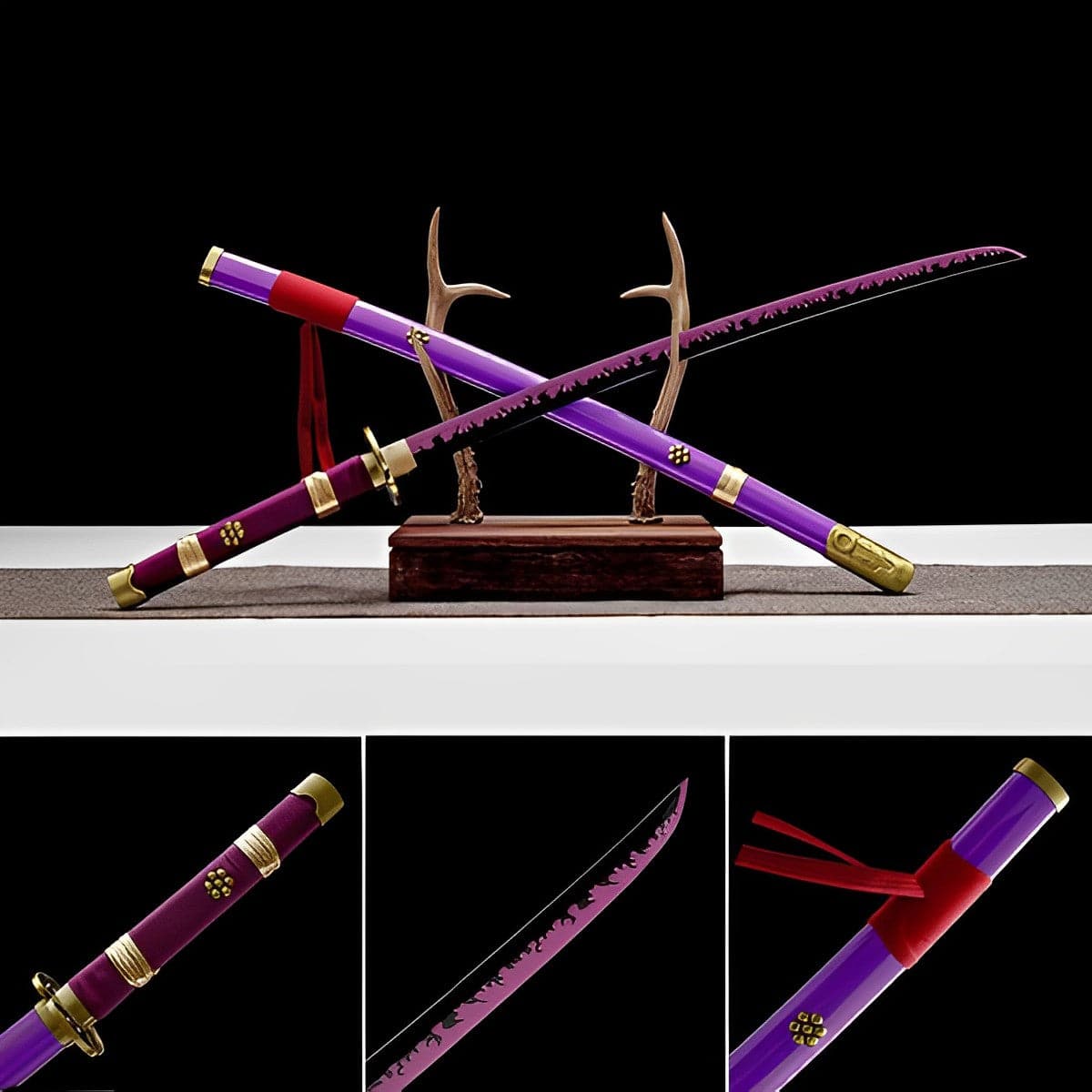

Chapter 5: LOONG BLADE’s Modern Interpretation

While honoring tradition, we’ve innovated:

- Laser-Guided Clay Application: Ensures 0.1mm precision in pattern placement

- Cryogenic Post-Quench: Liquid nitrogen treatment enhances crystal structure

- Hamon Authentication: Each blade includes microscopic hamon imaging