High carbon steel

Introduction: The Backbone of Premium Edged Tools

With a carbon content ranging from 0.6% to 1.4%, high carbon steel represents the gold standard for bladesmithing and precision tool manufacturing. This exceptional alloy transforms under a smith’s skilled hands – capable of achieving unparalleled edge retention through heat treatment while maintaining the structural integrity demanded by professional craftsmen. At [Your Brand Name], we utilize premium high carbon steels like 1095, W2, and 80CrV2 to forge blades that honor tradition while meeting modern performance standards.

Chapter 1: Metallurgical Properties That Define Performance

The Carbon Advantage

- Crystal Structure: Increased carbon forms harder cementite (Fe3C) within the ferrite matrix

- Heat Treatment Range: Achieves HRC 58-64 after proper quenching (compared to HRC 40-55 for mild steel)

-

Critical Temperatures:

- Austenitization: 1500-1600°F (815-870°C)

- Quench Mediums: Oil (moderate speed), Water (fast), or specialized polymer solutions

Comparative Steel Properties

| Property | High Carbon (1.0%C) | Medium Carbon (0.4%C) | Stainless (440C) |

|---|---|---|---|

| Hardness | HRC 60+ | HRC 50 | HRC 58 |

| Toughness | Moderate | High | Low |

| Edge Life | 3-5x Longer | 2x Longer | 1-2x Longer |

Chapter 2: Precision Heat Treatment Techniques

Optimizing The Blade’s Potential

-

Quenching

- Oil-quenched: Balanced hardness/toughness (ideal for knives)

- Water-quenched: Maximum hardness (traditional Japanese swords)

- Interrupted quench: Specialized technique to prevent stress cracks

-

Tempering

- 300-400°F (150-200°C): Maintains maximum hardness for cutting tools

- 400-500°F (200-260°C): Optimal balance for combat blades

- 500-600°F (260-315°C): Spring temper for flexibility

Common Pitfalls To Avoid

✖ Overheating during grinding (causes temper softening)

✖ Insufficient preheat before welding (leads to hydrogen cracking)

✖ Improper austenitizing time (results in incomplete transformation)

Chapter 3: Applications Across History & Industry

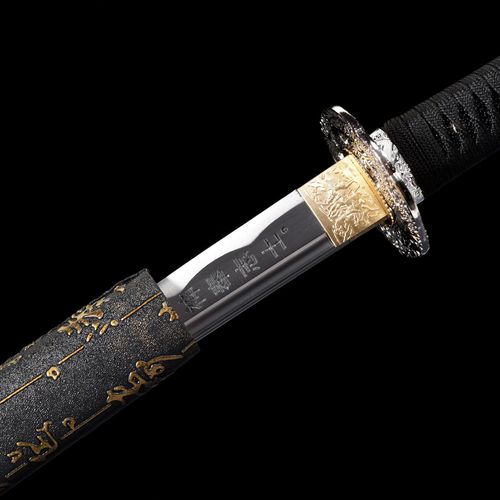

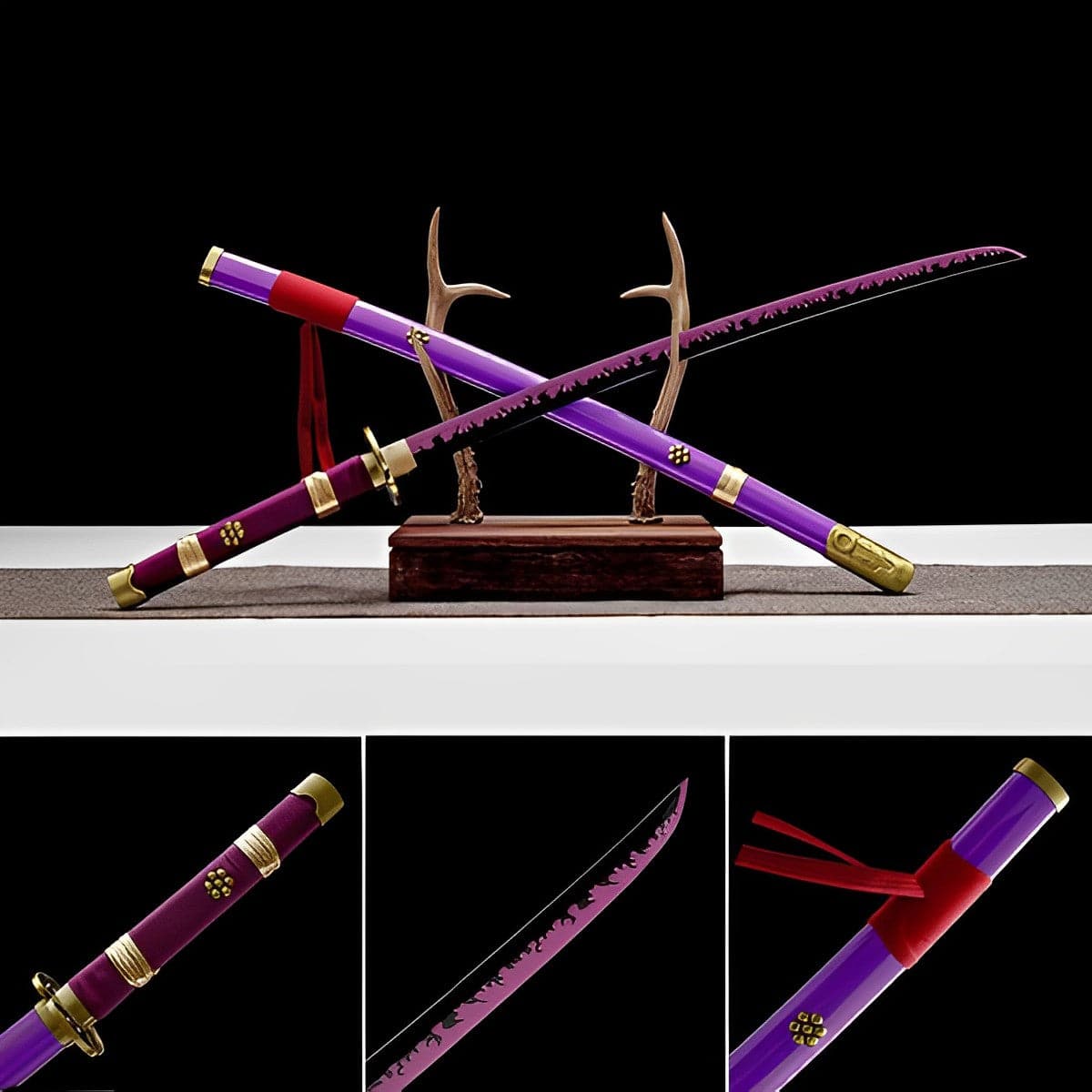

Traditional Bladesmithing

- Katana (玉鋼): Japanese swords using tamahagane (1.0-1.4%C)

- Damascus Steel: Pattern-welded composites with high carbon layers

- Viking Swords: Ulfberht blades with crucible steel (~1.2%C)

Modern Cutting Tools

✔ Surgical instruments

✔ Industrial shears

✔ High-end kitchen cutlery

Chapter 4: Working With High Carbon Steel – Pro Tips

Forging Best Practices

- Working Temperature: 1800-2000°F (bright yellow heat)

- Hammer Control: Avoid thinning below 1/8” before final grinding

- Thermal Cycling: Normalize 3x before hardening

Machining & Finishing

- Grinding: Use aluminum oxide belts, keep steel cool

- Polishing: Progress through 220-2000 grit before buffing

- Etching: Ferric chloride reveals grain structure

Conclusion: The Smith’s Timeless Choice

High carbon steel remains the undisputed champion for edge tools because it offers:

- Customizable Performance through precise heat treatment

- Superior Edge Retention unmatched by other alloys

- Historical Authenticity for traditional reproduction blades