Folding pattern steel/Damascus steel in China

Introduction: The Living Canvas of Bladesmithing

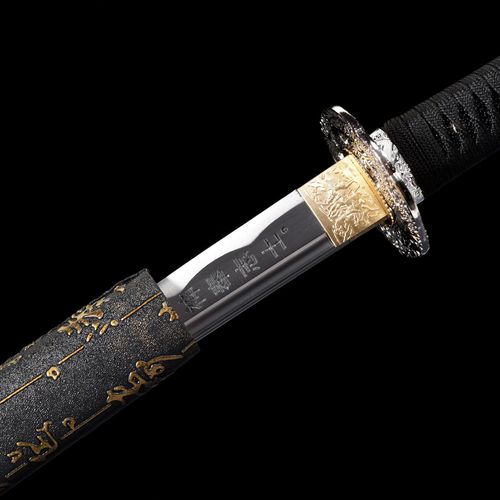

Pattern-welded steel represents one of mankind's most remarkable metallurgical achievements—where function and artistry merge in shimmering waves of folded metal. Known historically as Damascus steel (or jinsu 金素钢 in Chinese), this legendary material has graced the blades of warriors, the workshops of artisans, and the collections of emperors for over two millennia.

At [Your Brand Name], we preserve these ancient techniques while incorporating modern metallurgy to create blades that honor tradition without compromising performance.

Chapter 1: The Alchemy of Pattern Formation

The Dance of Fire and Iron

Creating pattern-welded steel involves a meticulous process:

- Stacking – Alternating layers of high-carbon and low-carbon steel

- Forging – Heating to 1300-1500°C and hammer-welding into a solid billet

- Folding – Repeatedly doubling the layers (typically 8-16 times)

- Twisting/Diffusion – Manipulating the billet to create unique patterns

Modern Insight: Contemporary metallurgists now recognize the nanostructures (carbon nanotubes and nanowires) that gave ancient Damascus steel its legendary properties.

Legendary Patterns Through History

| Pattern Type | Cultural Origin | Characteristic Appearance |

|---|---|---|

| Rose Damascus | Middle East | Floral, circular motifs |

| Mokume-gane | Japan | Wood-grain texture |

| Jinsu | China | Golden wire-like veining |

| Ladder Pattern | Europe | Parallel striations |

Chapter 2: Damascus Steel - A Legacy Across Civilizations

The Original "Watered Steel"

- Middle Eastern Roots: Named for Damascus, Syria, but likely originating from Indian wootz steel ingots

- Chinese Mastery: Han Dynasty (206 BC–220 AD) texts describe jinsu blades that could "cut through falling silk"

- Japanese Adaptation: Tamahagane steel folding techniques produced similar aesthetic results

Why Ancient Damascus Disappeared

- Lost around 1700 AD due to:

- Depletion of trace element mines (vanadium, chromium)

- Breakdown of trade routes for Indian wootz ingots

- Guarded artisan guild secrets dying with masters

Chapter 3: Modern Recreation & Scientific Insights

20th Century Rediscovery

- 1980s: Stanford researchers identified carbide banding nanostructures

- Current methods include:

- Powder metallurgy for consistent alloy distribution

- Acid etching enhancement (5-15% ferric chloride solutions)

- Computer-modeled stacking for predictable patterns

Performance Advantages

- Micro-serrations: Natural pattern creates microscopic teeth

- Shock absorption: Layered structure prevents catastrophic failure

- Edge retention: High-carbon layers maintain sharpness

Chapter 4: Applications Beyond Blades

Functional Artistry

- Jewelry: Mokume-gane wedding rings with 250+ layers

- Architecture: Decorative structural elements in luxury buildings

- Automotive: High-end knife-edged piston rings

Collector Considerations

-

Authenticity Check:

✓ Real Damascus shows depth under 10x magnification

✓ Acid-etched fakes lack layered microstructure -

Maintenance:

✓ Use renaissance wax for preservation

✓ Avoid abrasive cleaners that dull patterns

Conclusion: The Eternal Allure of Living Metal

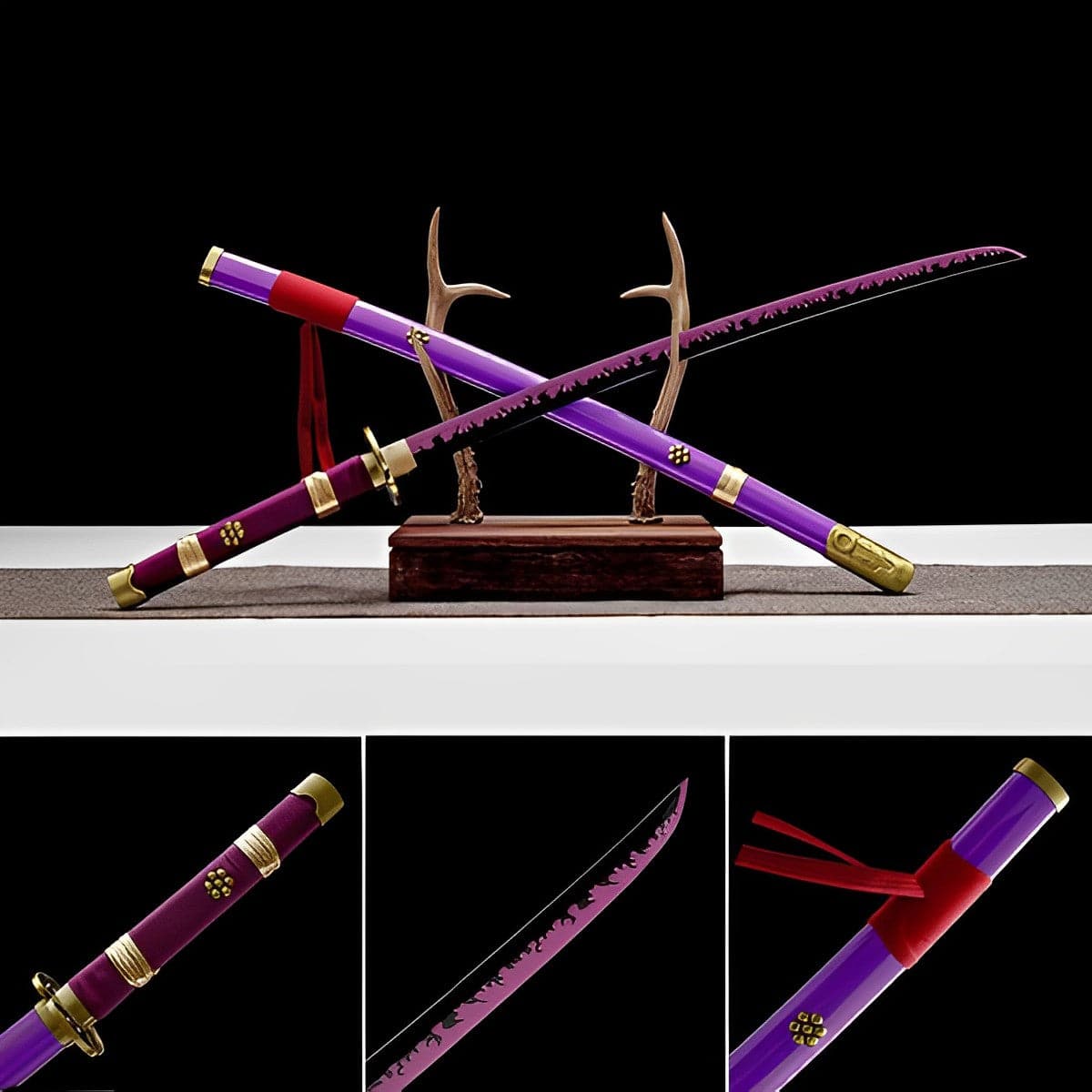

From the curved shamshirs of Persian warriors to the tanto carried by modern special forces, pattern-welded steel continues to captivate because it represents:

- Human Ingenuity – Transforming raw elements into functional art

- Cultural Bridge – Connecting metallurgical traditions across continents

- Timeless Performance – Still outperforming many homogeneous alloys