Medium Carbon Steel

Introduction: The Balanced Performer

With a carbon content of 0.30% to 0.60%, medium carbon steel represents the ideal compromise between strength and workability in steel alloys. This versatile material serves as the backbone of industrial manufacturing, offering engineers and fabricators a reliable solution that responds exceptionally well to heat treatment. At [Your Brand Name], we leverage medium carbon steel's unique properties to create durable components that withstand demanding operational conditions.

Chapter 1: Metallurgical Characteristics

Optimal Carbon Range Benefits

- Enhanced Strength: Tensile strength ranges from 570-700 MPa (compared to 400-550 MPa for low carbon steel)

- Heat Treatment Responsiveness: Achieves hardness up to HRC 55 through quenching and tempering

- Microstructure: Balanced ferrite-pearlite composition that transforms to martensite when hardened

Comparative Mechanical Properties

| Property | Medium Carbon (0.45%C) | Low Carbon (0.15%C) | High Carbon (0.90%C) |

|---|---|---|---|

| Yield Strength | 490 MPa | 330 MPa | 620 MPa |

| Elongation | 15-20% | 25-30% | 8-12% |

| Impact Toughness | 40-60 J | 80-100 J | 20-40 J |

Chapter 2: Industrial Applications

Core Manufacturing Uses

- Automotive Components: Connecting rods, axle shafts, and gear blanks

- Machinery Parts: Hydraulic rams, spindles, and high-strength fasteners

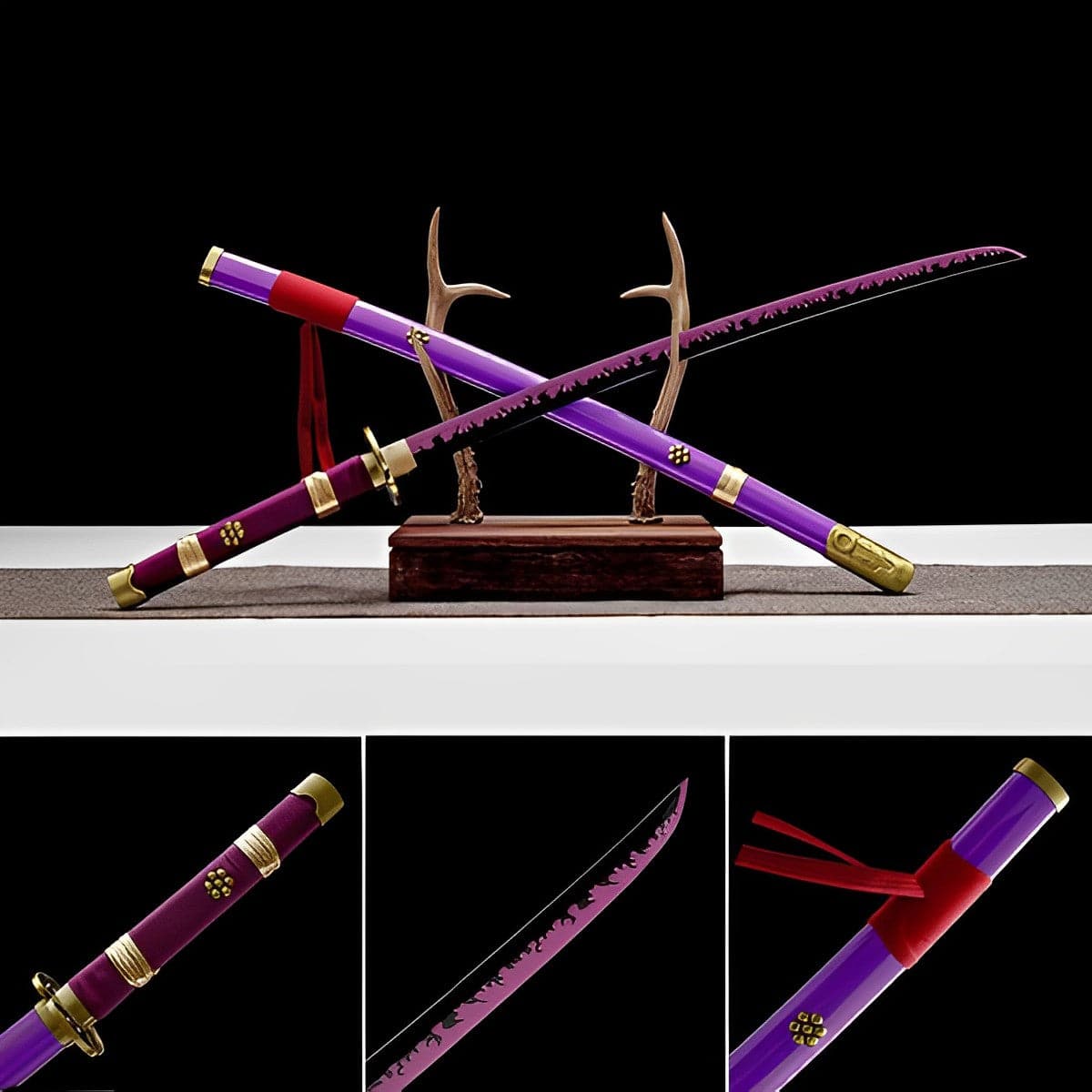

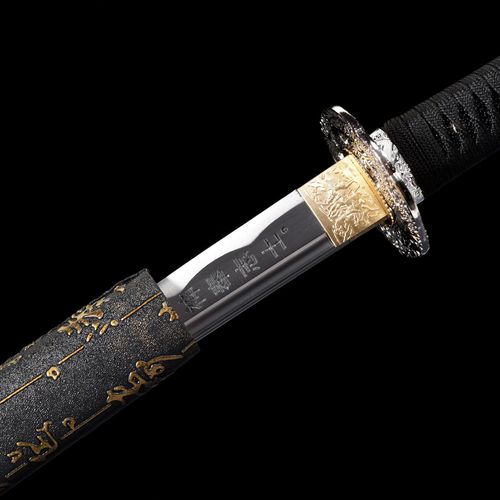

- Tooling Applications: Dies, molds, and cutting implements requiring impact resistance

Specialized Applications

✔ Railway wheels and tracks

✔ Pressure vessel components

✔ Agricultural equipment components

Chapter 3: Processing Considerations

Best Practices for Fabrication

- Forging Temperature Range: 2150°F - 2300°F (1175°C - 1260°C)

-

Machinability Improvements:

- Annealing (hardness HB 180-220)

- Lead or sulfur additions for free-machining grades

-

Welding Procedures:

- Preheat to 300-500°F (150-260°C)

- Post-weld heat treatment at 1100°F (595°C) for stress relief

- Recommended processes: SMAW (7018 electrodes), GTAW

Heat Treatment Options

- Quench & Temper: Oil quench from 1550°F (845°C), temper at 400-1200°F (200-650°C)

- Normalizing: Heat to 1650°F (900°C), air cool

- Case Hardening: For selected applications requiring surface hardness

Chapter 4: Corrosion Protection Strategies

Surface Treatment Options

| Method | Thickness | Protection Level | Cost |

|---|---|---|---|

| Zinc Plating | 5-25 μm | Moderate | Low |

| Powder Coating | 50-150 μm | High | Medium |

| Nitriding | 0.1-0.5 mm | Excellent | High |

Maintenance Recommendations

- Regular inspection for surface damage

- Immediate treatment of scratches or chips in coating

- Avoidance of chloride-rich environments when unprotected

Conclusion: The Versatile Performer

Medium carbon steel remains indispensable in modern manufacturing because it offers:

- Optimal Balance of strength and ductility

- Cost-Effective Performance for critical components

- Adaptability through various heat treatment options

- Proven Reliability across countless industrial applications

Tags: